St. Petersburg; Oil industry

Contractors: Inline Group

Product: Inline Group IKSAR (XR) Platform for Auxiliary Reality Devices

Project date: 2019/09 - 2021/10

2021: Reduced Logistics Costs for Installation Supervision

Augmented Reality Platform "IKSAR" will help Gazprom Neft"" several times reduce the cost of logistics chief installation work. This was announced on November 2021 by the company. Inline Group JSC.

The pandemic stimulated the search for IT tools for remote interaction between contractors and Gazprom Neft employees.

The digital product "Remote control of chief installation works using AR technology" will achieve maximum employee safety and savings.

«Any industrial equipment in the oil and gas sector requires careful and impeccable maintenance. As a rule, only manufacturers or narrow-profile specialists can provide it. In a pandemic, we cannot guarantee the logistics of such a specialist from another city or from abroad. Augmented reality technologies remove time and distance restrictions, allowing you to immediately start work, save time, money, and most importantly - without neglecting the safety and health of people»,said the head of the AR/VR center "Gazprom Neft" Vladislav Murlenko.

«Augmented reality at work minimizes human error. In manufacturing and the industrial sector, the price of such a mistake can be very high, so we develop tools taking into account the individual requirements of the company, taking into account the wishes of each participant in the business chain. Our main goal is to create a product that meets all the customer's safety standards and requirements» ,noted Igor Gulyansky, founder of IKSAR, director of innovation at Inline Group JSC.

At the testing stage with the help of industrial AR glasses and the IKSAR software platform, Gazprom Neft specialists carried out a chief installation of the internal devices of the vacuum column. The domestic software platform "IKSAR" has established itself as a reliable tool for organizing group and individual video communication between specialists at the computer and operators on the production site with AR glasses. During the test, the specialists of IKSAR and Gazprom Neft confirmed the intended hypotheses, which allowed us to go to the stages of creating and refining MVP. According to the calculations of Gazprom Neft specialists, the final implementation of the product at more than 100 sites within the company will reduce the time for chief installation work and almost completely reduce logistics costs.

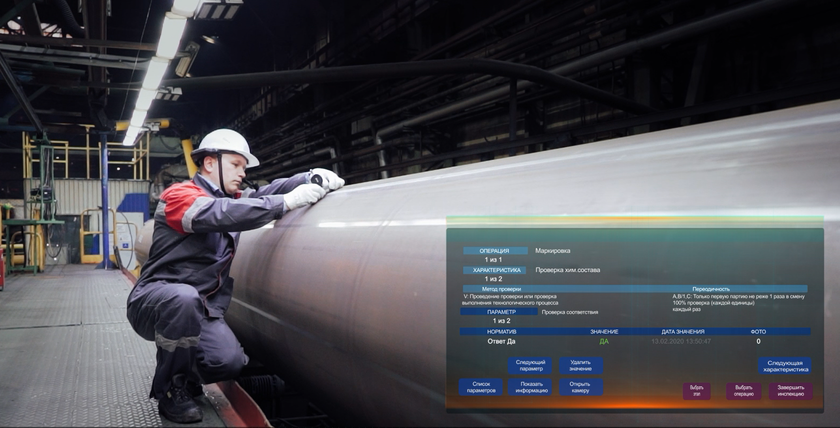

Application of "Iksar" platform on OMK

On May 29, 2020, the company Inline announced that "" Gazprom neft together "" United Metallurgical Company they are using auxiliary technologies and devices augmented reality to perform inspection control operations on the basis of the domestic platform. "IKSAR

The digital transformation of manufacturing companies covers more and more areas, changing the usual way of performing operations.

One of these areas is inspection control, which plays a crucial role in analyzing the quality of products in the early stages of their manufacture.

Using the IKSAR platform, the inspector receives a task in digital format directly to a mobile device, in the role of which smart industrial performance points act.

Leaving your hands free, with the help of voice commands, the worker enters indicators.

According to the graphic and text instructions on the glasses screen, the specialist fills the check lists, performs photos and video recording of deviations.

Once the transaction is complete, the structured digital information is immediately available for review by all stakeholders.

PJSC Gazprom Neft expects that the use of IKSAR in combination with smart glasses can significantly increase the accuracy and speed of operations.

Application of the IKSAR platform at the Moscow refinery

As part of the Digital Warehouse project at the Moscow Oil Refinery, along with robotic tools to support the work of an employee, the IKSAR software platform is used in combination with smart industrial glasses. This became known on May 27, 2020.

Warehouse employees perform ongoing operations by receiving step-by-step graphical instructions on the screen of smart glasses in online and offline modes. Voice control of operations on smart glasses allows you to leave the hands of employees free.

Video call allows you to solve non-standard situations in real time.

The integration of the IKSAR platform with robotic storage equipment can further bring additional benefits for improving production safety, optimizing costs and improving the speed of operations.